Scan QRCode

Jingxi Zhixing officially announces its fourth generation MagneRide ® The magnetorheological suspension has completed its global layout in China, Europe, and North America, achieved production capacity breakthroughs through comprehensive localization, and officially opened the inclusive era with the "Global magnetorheological Year" relying on the "China Leading, Global Collaboration" strategy. On October 8th, Jingxi Zhixing successfully held a magnetorheological European network seminar at its research and development center in Krakow, Poland. Liu Xihe, the global CEO of the company, stated at a seminar in Poland that Jingxi Zhixing has built a collaborative production network covering three continents, MagneRide ® The supply of magnetorheological suspension will form a tripartite pattern of China, Europe, and North America, further establishing the "global magnetorheological era".

Jingxi Zhixing Global CEO Liu Xihe said at the online seminar in Poland that, MagneRide ® Supply of magnetorheological suspension

A pattern will be formed where China, Europe, and North America are on par

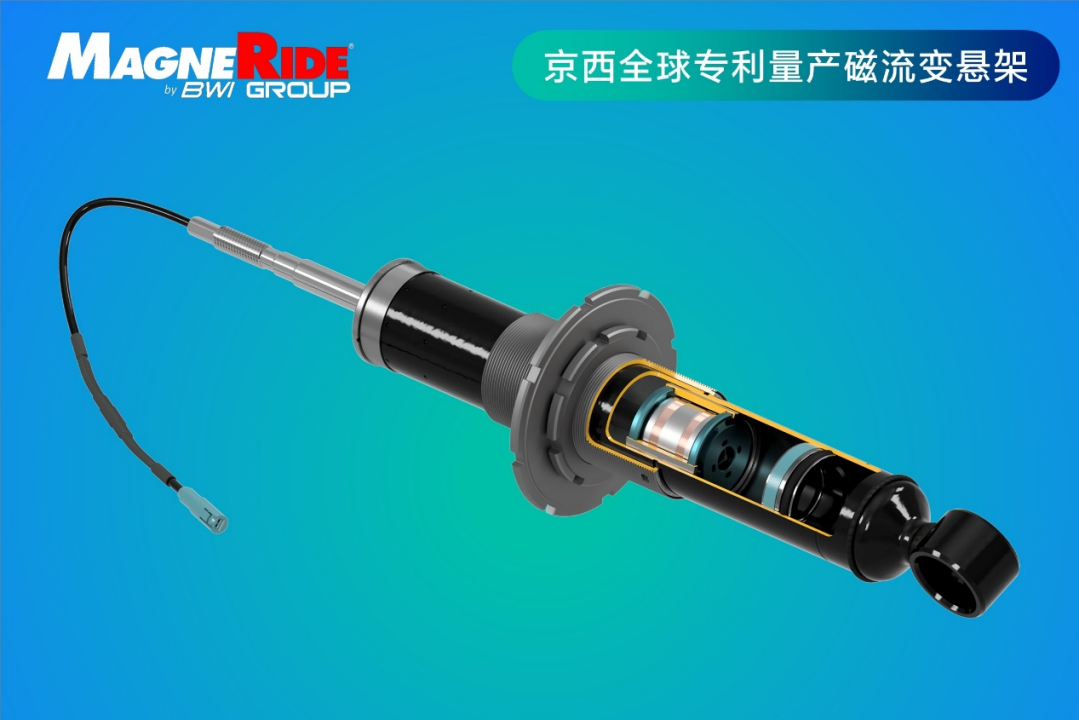

This online seminar comprehensively showcased the high-quality production capacity and global collaboration system of the Jingxi Zhixing magnetorheological suspension production line. The innovative "cloud factory exploration" segment was the first to connect the company's European manufacturing center - the Krasno factory in Poland, and announced the 11 millionth MagneRide from Jingxi Zhixing worldwide ® The magnetorheological shock absorber is offline. The Krasno factory has a history of 81 years and continues to supply car brands such as Ferrari and Lamborghini through digital upgrades. Ferrari, Lamborghini, Cadillac, Audi, Mustang and other overseas luxury and ultra luxury brands regularly purchase MagneRide produced by Jingxi Zhixing's factories in Poland and Mexico ® The magneto rheological suspension system has been applied in over 100 vehicle models. Alessandro Manca, Senior Vice President of Sales, Marketing, and Project Management at Jingxi Zhixing, stated that Jingxi Zhixing has always adhered to the concept of "customer-centric" and built a full chain agile system from technology research and development to production delivery by quickly responding to market demands. To continuously promote MagneRide ® The top technology of magnetorheological suspension is being popularized, and Jingxi Zhixing is relying on China's large-scale manufacturing capabilities to achieve cost optimization through economies of scale. The "Cloud Factory Exploration" segment of this event also revealed the digital production line of magnetorheological shock absorbers in the Shenzhen factory. Jingxi Zhixing Shenzhen factory is ensuring the quality control of every fourth generation MagneRide through full process quality control ® High quality delivery of magnetorheological shock absorbers ensures the application of multiple domestic vehicle models. The magnetorheological suspension production line of the Shenzhen factory has been put into operation since March this year, and the Zhangjiakou factory will also put into operation the magnetorheological suspension production line this year. Both regions in China will jointly increase the annual production capacity of Jingxi Zhixing's domestic magnetorheological shock absorbers to 2 million units. The recently successful global debut of the Deep Blue L06 pure electric long-range magnetorheological laser intelligent coupe has been equipped with MagneRide ® Magnetorheological suspension. The magnetorheological suspension provides particularly outstanding performance in body control for the Deep Blue L06, which can suppress roll and transient pitch, especially in bumpy roads, high-speed bumps or speed bumps, flying slope impacts, fast turns and other scenarios. The body is more stable, greatly enhancing driving comfort.

Jiang Hairong, CEO of Shenlan Automobile, shared the extraordinary performance and super luxury experience brought by the application of magnetorheological suspension technology to Shenlan L06

Jiang Hairong, CEO of Deep Blue Automobile, shared at the online seminar the extraordinary performance and super luxury experience brought by the application of magnetorheological suspension technology to the Deep Blue L06. Jiang Hairong stated that the magnetorheological suspension provides the Deep Blue L06 with an ultimate handling experience comparable to supercars, balancing both sportiness and comfort. The magneto rheological system has the ability to adjust 1000 times per second, which not only retains a clear road feel but also filters out unnecessary bumps, greatly improving the user's driving comfort.

China, Europe, and America are favored by industry, academia, and research, and magnetorheological suspension leads the future

Representatives from the automotive industry, academia, and research communities in China, multiple European countries, and the United States elaborated on the consensus in the field of magnetorheological technology at an online seminar: the Jingxi Zhixing MagnaRide, which is protected by over 140 global patents ® Magnetorheological suspension technology will easily achieve "one suspension, a thousand experiences" with its full software control characteristics and scalable design, becoming a key suspension technology for automobiles to cope with future intelligent trends and "all scenario, adaptive".

Deep Blue L06 pure electric long endurance magnetorheological laser intelligent coupe has been equipped with MagneRide ® Magneto rheological suspension

Professor Bogdan Spinski, who specializes in magnetorheological fluid research at AGH University of Technology in Poland, analyzed from an academic perspective that magnetorheological fluid, a "smart liquid" technology, promotes the evolution of automotive suspension towards revolutionary valve free intelligent suspension through closed-loop control of perception, analysis, regulation, and reaction. By using software intelligent tuning and simulation technology to shorten the development cycle, combined with sensor innovation to achieve more accurate vehicle dynamic prediction, it has already been adapted to future application scenarios in advance. MagneRide ® The core working principle of magnetorheological suspension is to achieve 1000 damping adjustments per second through magnetorheological fluid, and the valve free design ensures response speed and reliability; The system relies on sensors to collect real-time vehicle dynamic data, combined with dynamic algorithms, to form a closed-loop control logic of "perception calculation execution". Including one of the inventors of the first generation magnetorheological shock absorbers in the United States, Jingxi Zhixing's R&D technology teams from China, Europe, and the United States, conducted multidimensional technical analysis and focused on exploring MagnaRide ® The development history of magnetorheological suspension technology, advantages over solenoid valve suspension, adaptability in software defined vehicles, and performance optimization through software tuning were discussed, and expectations were expressed for the future application potential of magnetorheological suspension. Equipped with the fourth generation MagneRide ® Vehicles with magnetorheological suspension can achieve a perfect balance of handling, comfort, and safety at a speed of 100 kilometers per hour through full stack self-developed software and hardware collaboration. The adjustment is made every 2.7 centimeters, combined with an extremely wide damping range, eliminating driving discomfort and upgrading the experience.

MagnaRide ® Magnetorheological suspension technology will easily achieve "one suspension, a thousand experiences" with full software control characteristics and scalable design

In terms of software, MagneRide ® The software system and OTA upgrade of magnetorheological suspension enable car manufacturers and users to achieve software defined vehicles, evolving into ever-changing driving modes and bringing infinite possibilities. The digital control architecture of magnetorheological suspension supports deep integration with ADAS vision system, and remote update of suspension parameters is achieved through OTA; The software driven tuning capability provides fine adjustment capabilities that other suspension systems do not have, allowing the vehicle to adapt to different driving scenarios, such as dynamic switching between sport mode and comfort mode. In order to visually present the performance of vehicles in practical applications, Jingxi Zhixing also invited rally racer Tomasz Czopik to drive MagneRide on the track in Krakow, Poland ® Magnetorheological suspension vehicles have demonstrated the improvement of handling and comfort, as well as outstanding performance, in complex working conditions such as high-speed cornering, rapid acceleration, rapid deceleration, and rural roads on the track. Looking back at the first to fourth generations, MagneRide ® The magnetorheological suspension system continues to make breakthroughs in durability, electrical compatibility, control algorithm accuracy, and diagnostic functions. Now, with the expansion of production capacity and technological iteration in the production base, Jingxi Zhixing is leading the world's top suspension technology to benefit a wider range of users through cost optimization and cross vehicle adaptation, laying a solid foundation for building a safer, more comfortable, and intelligent future travel ecosystem.

AMS2024 Exhibition Guide | Comprehensive Exhibition Guide, Don't Miss the Exciting Events Online and Offline

Notice on Holding the Rui'an Promotion Conference for the 2025 China (Rui'an) International Automobile and Motorcycle Parts Exhibition

On September 5th, we invite you to join us at the Wenzhou Auto Parts Exhibition on a journey to trace the origin of the Auto Parts City, as per the invitation from the purchaser!

Hot Booking | AAPEX 2024- Professional Exhibition Channel for Entering the North American Auto Parts Market

The wind is just right, Qianchuan Hui! Looking forward to working with you at the 2024 Wenzhou Auto Parts Exhibition and composing a new chapter!

Live up to Shaohua | Wenzhou Auto Parts Exhibition, these wonderful moments are worth remembering!

Free support line!

Email Support!

Working Days/Hours!